Driveway

What is Pervious Concrete?

Pervious concrete is a durable concrete pavement made with approximately 20% interconnected air voids. Like conventional concrete, it is made from a mixture of cement, coarse aggregates, and water. However, it contains little or no sand, which results in a porous open-cell structure that allows water to pass through it readily. A typical pervious concrete pavement system consists of 4-8 inches of pervious concrete, with 4-8 inches of crushed drain rock between the concrete and the base soil. No stormwater pipes, drains or tanks are necessary.

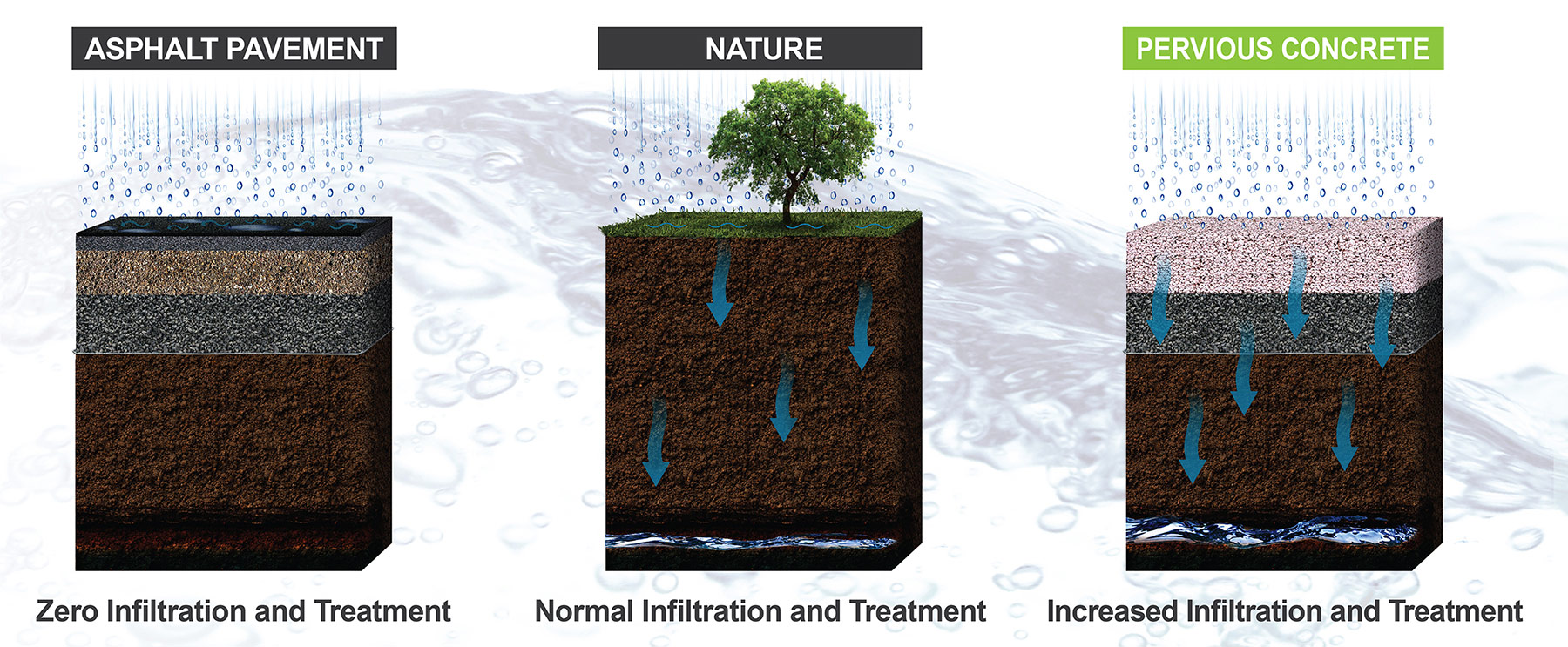

Environmentally Regenerative: Infiltration, treatment and groundwater recharge

Pervious concrete pavement systems are fully recognized by the EPA as a best management practice for both on-site infiltration and treatment. As the water percolates through the open voids of the pavement and crushed rock base layer aerobic bacteria in the voids help to break down harmful pollutants and chemicals. Studies have found that pervious concrete naturally removes 94-100% of all pollutants from stormwater. The treated water then continues to infiltrate into the lower soil layers where it can replenish local groundwater sources, waterways, and aquifers. The crushed rock base layer also acts as a reservoir layer to hold excess water until the base soil is able to infiltrate it. Because of this reservoir, pervious concrete can in most cases outperform nature by allowing more water to infiltrate and be treated instead of becoming runoff.

Display More [+]

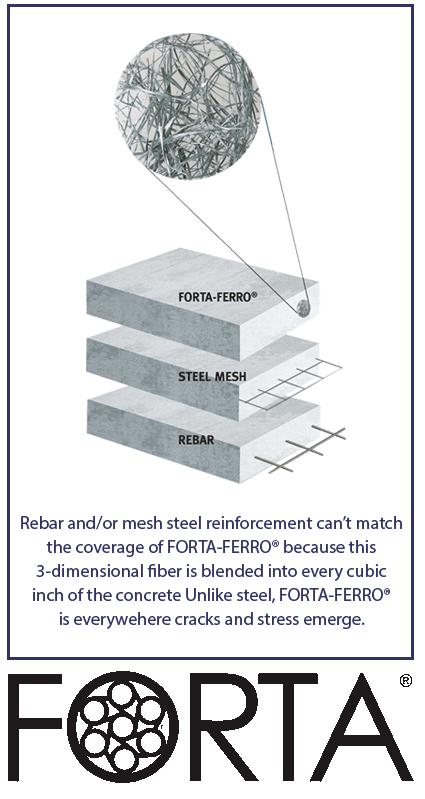

Multigenerational: FORTA Macrofibers

For a multigenerational house the life cycle of a product is very important. It requires a product that will not only last a hundred years, but maintain its usefulness for the entire length of that time. Typically, pervious concrete has a recommended 30-50 year life cycle. With Tah Mah Lah’s goals in mind we decided to use a product called Forta Ferro-Green, a synthetic polypropylene macrofiber. The macrofibers are incorporated into the concrete as it’s mixed, and when installed create a 3-dimensional mesh support system throughout the concrete. The inclusion of macrofibers increases the pervious concrete’s durability, reduces raveling and abrasion losses, and increases resistance to freeze-thaw conditions. By using the macrofibers the life expectancy of the pervious concrete is greatly increased and with proper care, should last for multiple generations.

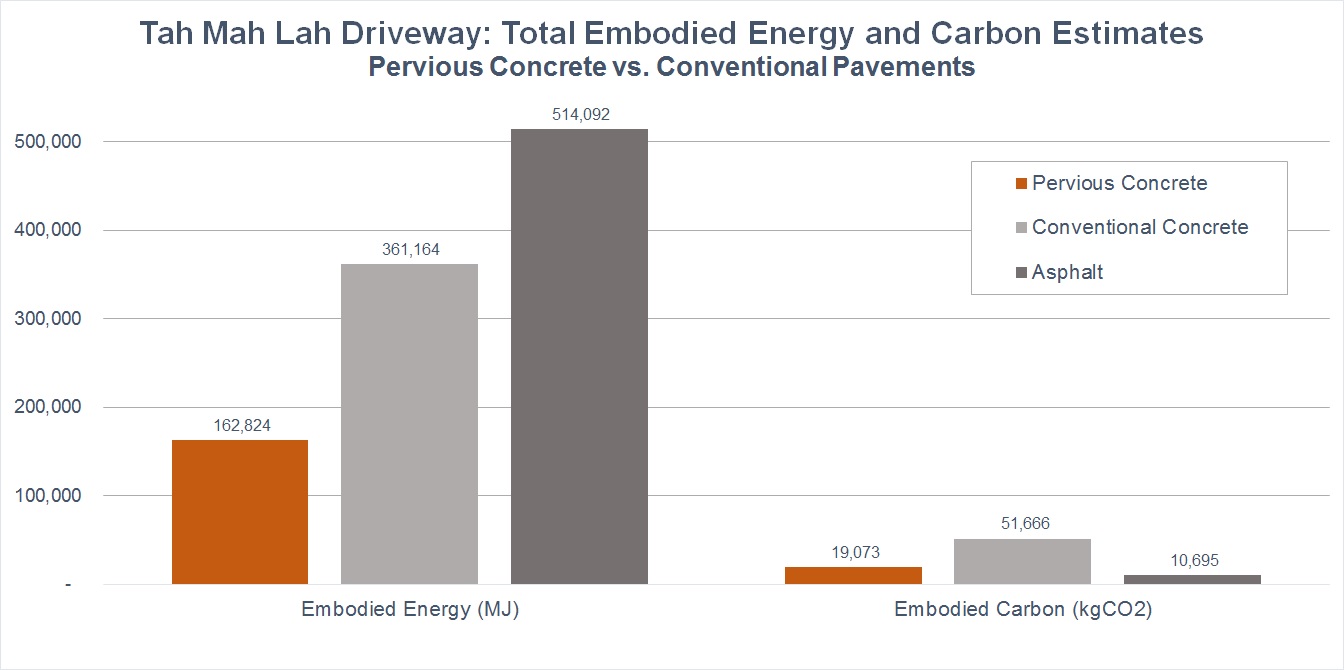

Global Sensibility: Reducing embodied energy and carbon and using recycled content

Reducing Embodied Energy and Carbon

Portland cement, a key ingredient in concrete, represents 5% of all global carbon emissions produced every year. Pervious concrete with its 20% air void structure and mix design - in which industrial by-products are utilized - lends itself to those seeking a lower carbon alternative. Reducing the amount of portland cement consumed produces significant reductions in embodied carbon. Upcycling the industrial by-products fly ash and slag into the pervious concrete led to the largest savings in embodied carbon, reducing it by 50%, and kept those materials out of a landfill. For Tah Mah Lah we reduced the driveway’s total embodied carbon by an estimated 64%, as compared to conventional concrete, through the omission of steel, reduction of portland cement consumption, and the use of industry by-products. When compared to asphalt we reduced the driveway’s total embodied energy by 71%.

Carbon Sequestration

Concrete, unlike other pavement materials, also sequesters carbon from the atmosphere as it cures through a process called carbonation. The chemical process of carbonation is when the calcium in the concrete is attacked by carbon dioxide in air or water, and is converted to calcium carbonate – densifying the concrete. Carbonation occurs only in the first several millimeters of conventional concrete surfaces that are exposed to air. With its matrix of air voids, pervious concrete exposes more of its surface area for carbonation than conventional concrete. Studies have indicated that including fly ash in the mix design can increase the carbonation rate up to 10 times that of traditional concrete. With more research, in the future we may find that pervious concrete is a carbon negative material.

Local Materials and Recycled Content

In lowering the impact of the driveway and carport at Tah Mah Lah we utilized several materials that helped to reduce the embodied energy. The fine grain aggregate used in the concrete was locally sourced from a quarry in Pleasanton, CA. Forta Ferro Green macrofibers contain some fibers that are made from 100% recycled-content. Reuse of the driveway’s original base layer reduced on-site excavation and waste. This also further reduced the carbon intensity by eliminating the need for new material extraction, hauling, and installation; leading to a 10% reduction of the embodied energy.

- The Project